Integrating electrolyzed water solutions into facility cleaning practices is an effective and straightforward way to enhance worker safety and environmental sustainability.

Understanding Electrolyzed Water

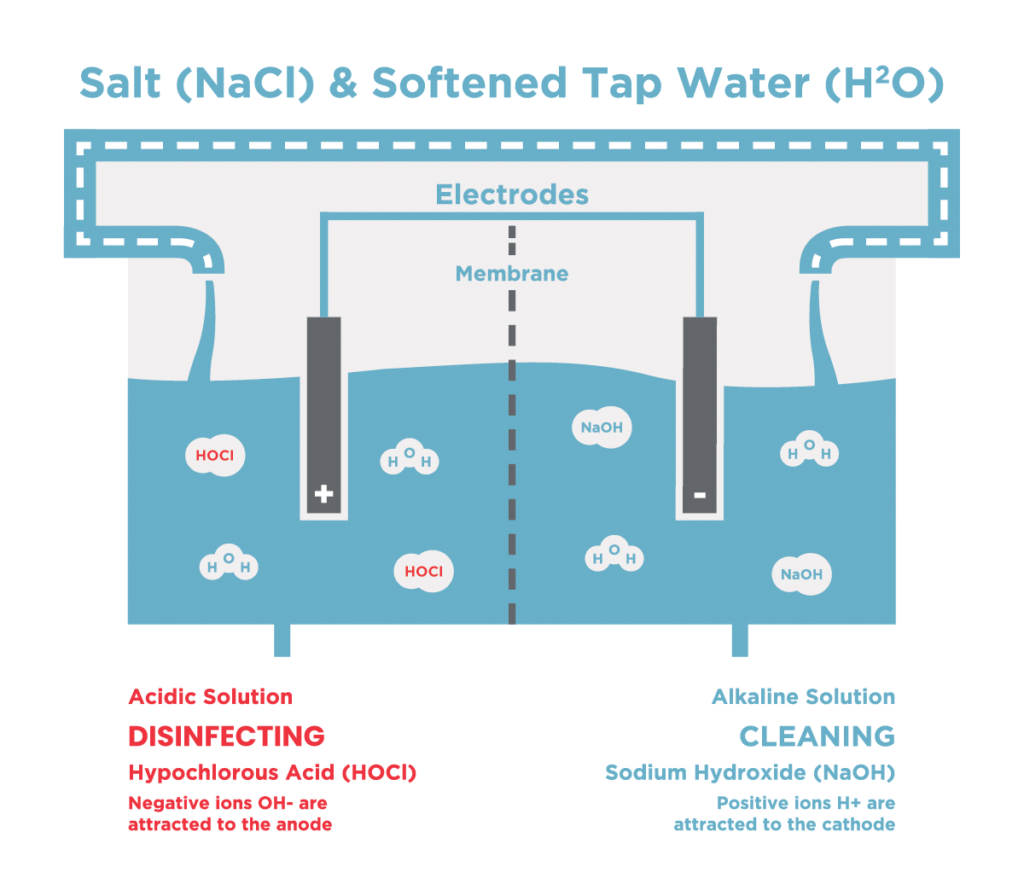

Electrolyzed water is produced through the electrolysis of a saline solution. This process involves passing an electric current through water containing dissolved sodium chloride (table salt), resulting in two distinct solutions:

- Hypochlorous Acid (HOCl): An effective disinfectant known for its strong antimicrobial properties.

- Sodium Hydroxide (NaOH): A cleaning agent capable of breaking down organic matter and grease.

The two solutions are separated and used for their respective cleaning and disinfecting properties.

Effectiveness as a Disinfectant

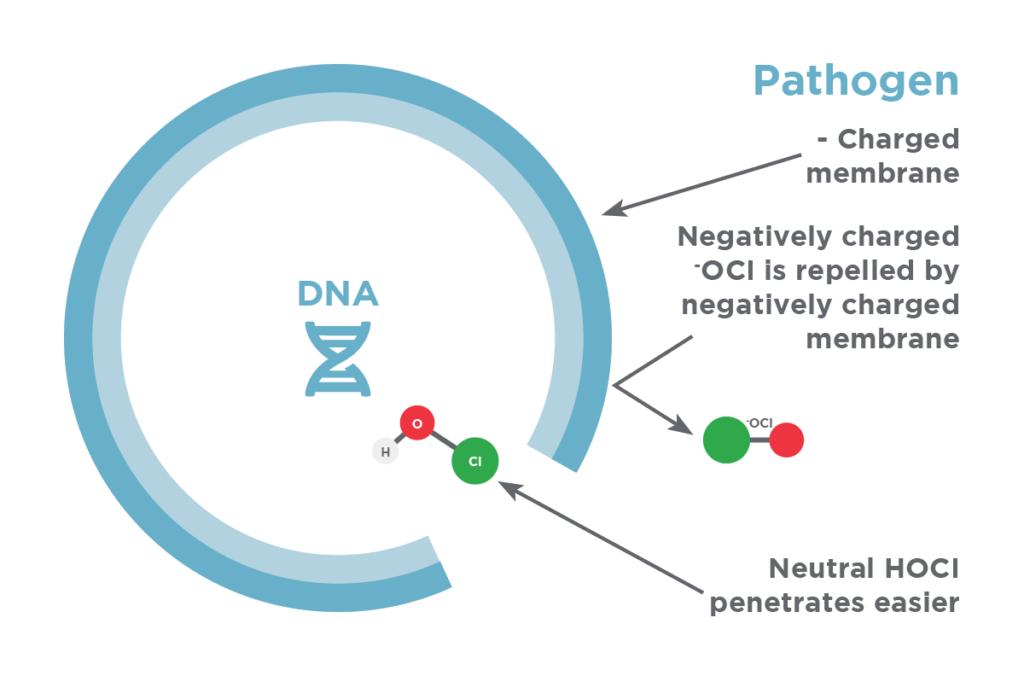

Hypochlorous acid, the primary disinfecting agent in electrolyzed water, is recognized for its broad-spectrum antimicrobial activity. It is effective against a wide range of pathogens, including bacteria, fungi, and viruses (including the flu, norovirus, and COVID-19).

Studies have demonstrated that hypochlorous acid can kill most common types of bacteria within five minutes of application. In addition, comparison testing of HOCl and bleach has shown that HOCl is more effective at surface disinfection of bacteria.

The NaOH cleaner, meanwhile, is a heavy-duty degreaser that breaks down fat, oil, and proteins. It’s effective against grease and mold, eliminates odor, and can be used on both hard or soft surfaces – including carpeting and upholstery. Like hypochlorous acid, it is approved by both the USDA and the FDA.

Most distinctively, both solutions do not contain VOCs, phenols or harsh chemicals, as they are produced with just two ingredients: water and salt. In fact, HOCl is the same substance our bodies produce to fight infection, which is why it’s also used for eye, wound, and veterinary care.

Applications of Electrolyzed Water and HOCl

The cleaning and disinfecting capabilities of electrolyzed water solutions are applicable to a wide range of industries. Some of the most common applications – specifically with regard to the hypochlorous acid disinfectant – include:

Healthcare Facilities

- Surface Disinfection: Effective for sanitizing and disinfecting high-touch surfaces like counters, doorknobs, and medical equipment.

- Infection Control: Used to disinfect patient rooms, operating theaters, and other critical areas to prevent the spread of pathogens.

- Electrostatic Spraying: Can be used in a sprayer to disinfect spaces, surfaces, and indoor environments.

Food Industry

- Food Preparation Areas: Ensures a hygienic environment by disinfecting cutting boards, countertops, and food processing equipment.

- Packaging Sanitization: Prevents contamination during the food packaging process.

Senior Living Communities

- Resident Rooms: Ensures a clean and germ-free environment in living quarters.

- Common Areas: Disinfects shared spaces like lounges, dining areas, and activity rooms.

- Medical Equipment: Safely sanitizes walkers, wheelchairs, and other assistive devices.

Hospitality Sector

- Housekeeping: Used for cleaning and disinfecting hotel rooms, lobbies, and communal areas.

- Kitchen Sanitation: Keeps commercial kitchen areas clean and free from germs without toxic residues.

- Guest Safety: Electrolyzed water is used in wellness areas like spas and pools for safe disinfection.

Education Facilities

- Classroom Cleaning: Safe for disinfecting desks, chairs, and other surfaces in schools and universities.

- Play Area Sanitation: Ideal for cleaning toys and play equipment in daycare centers and preschools.

- Cafeteria Hygiene: Helps maintain cleanliness in dining areas and kitchen facilities.

Industrial and Commercial Facilities

- Floor Cleaning: Ideal for large-scale cleaning of floors in warehouses and manufacturing plants.

- Equipment Maintenance: Safely removes grease and grime from machinery without damaging components.

Public Spaces & Recreational Facilities

- Transportation Hubs: Disinfects surfaces in airports, train stations, and buses.

- Sports Venues: Ensures cleanliness in locker rooms, gym equipment, and seating areas.

- Retail Stores: Keeps shopping carts, shelves, and checkout counters clean.

Residential Use

- Kitchen Cleaning: Disinfects cutting boards, sinks, and countertops.

- Bathroom Hygiene: Cleans and sanitizes toilets, showers, and sinks.

- Pet Care: Used for cleaning pet bowls, toys, and living spaces safely.

These applications demonstrate the adaptability of electrolyzed water and especially HOCl as a safer, non-toxic, and environmentally friendly alternative to traditional cleaning and disinfecting methods.

Advantages of Integrating Electrolyzed Water into Facility Cleaning Practices

Incorporating electrolyzed water into facility cleaning routines is not only a technological innovation but also a practical, scalable solution to modern cleaning challenges. Its advantages go far beyond its ability to clean and disinfect, offering significant improvements in health, safety, sustainability, and operational efficiency.

LEARN MORE about the harms of toxic cleaning chemicals for workers

1. Worker Health and Safety

Traditional cleaning chemicals often pose health risks, including respiratory issues, skin irritations, and long-term illness like cancer. Electrolyzed water is inherently non-toxic and safe to use, reducing exposure to harsh chemicals that can cause adverse health effects such as respiratory irritation, allergic reactions, and chemical burns. Unlike traditional cleaning agents, it produces no volatile organic compounds (VOCs) or harmful fumes, which makes it especially beneficial in enclosed spaces with limited ventilation.

Traditional cleaning chemicals often pose health risks, including respiratory issues, skin irritations, and long-term illness like cancer. Electrolyzed water is inherently non-toxic and safe to use, reducing exposure to harsh chemicals that can cause adverse health effects such as respiratory irritation, allergic reactions, and chemical burns. Unlike traditional cleaning agents, it produces no volatile organic compounds (VOCs) or harmful fumes, which makes it especially beneficial in enclosed spaces with limited ventilation.

Key benefits for worker health include:

- Reduced Risk of Injuries: With no corrosive properties, electrolyzed water minimizes the risk of chemical burns or injuries due to accidental contact.

- Improved Air Quality: Absence of VOCs and chemical fumes ensures better indoor air quality, particularly crucial for workers with respiratory conditions.

- Simplified Safety Protocols: Lower toxicity reduces the need for extensive personal protective equipment (PPE) and complex handling guidelines, streamlining cleaning operations. There is no need to wear PPE when handling electrolyzed water solutions.

2. Environmental Sustainability

Electrolyzed water aligns with growing global efforts to promote sustainable practices. Its eco-friendly nature stems from its ability to decompose into simple, non-harmful substances (water and a small amount of salt). This reduces both the environmental footprint of cleaning operations and the pollution associated with traditional chemical disinfectants.

Its production and use reduce the reliance on hazardous chemicals, contributing to greener cleaning practices. Additionally, electrolyzed water solutions can be generated on-site, eliminating waste from single-use plastic bottles and reducing product transportation costs and the associated carbon footprint.

Key sustainability benefits include:

- Minimized Chemical Waste: On-site production eliminates the packaging and disposal of chemical containers.

- Reduced Carbon Footprint: By avoiding the transportation and distribution of conventional cleaning products, facilities can lower greenhouse gas emissions.

- Safer Discharges: Wastewater containing electrolyzed water has negligible environmental impact compared to chemical-laden discharges.

3. Cost Efficiency

The ability to generate electrolyzed water on-site offers significant cost-saving opportunities:

- Eliminating Product Procurement Costs: Facilities no longer need to purchase a wide range of chemical cleaners and disinfectants, which reduces supply chain dependencies and costs.

- Labor Costs: By reducing the health risk for employees, using electrolyzed water solutions can also impact the bottom line by improving productivity, minimizing sick days, and even preventing costly worker’s compensation claims.

- Storage Savings: Electrolyzed water eliminates the need for extensive storage space for chemical products.

- Longevity of Equipment and Surfaces: Unlike harsh chemicals that can corrode surfaces and machinery, electrolyzed water is gentle, extending the lifespan of facility assets.

4. Enhanced Cleaning Efficiency

Electrolyzed water’s dual production of hypochlorous acid and sodium hydroxide enables it to serve as both a disinfectant and a cleaning agent. This versatility allows for simplified cleaning protocols and the replacement of multiple chemical products with a single solution.

Electrolyzed water’s dual production of hypochlorous acid and sodium hydroxide enables it to serve as both a disinfectant and a cleaning agent. This versatility allows for simplified cleaning protocols and the replacement of multiple chemical products with a single solution.

Efficiency advantages include:

- Streamlined Processes: Cleaning staff can perform multiple tasks (e.g., cleaning and disinfecting) in a single step, saving time and effort.

- High Efficacy: Hypochlorous acid is a fast-acting disinfectant that effectively kills bacteria, viruses, fungi, and spores on contact, often within seconds.

- Residue-Free Cleaning: Electrolyzed water leaves no sticky or harmful residues, eliminating the need for post-cleaning rinsing in most applications.

5. Adaptability Across Industries

Electrolyzed water’s effectiveness and safety make it suitable for a variety of industries, including healthcare, education, hospitality, and manufacturing. Its adaptability allows facilities to customize its application to meet specific cleaning and disinfecting needs.

Examples of cross-industry adaptability:

- Healthcare: Disinfecting sensitive medical equipment and high-touch surfaces.

- Education: Safely cleaning classrooms, playgrounds, and cafeterias.

- Hospitality: Maintaining hygienic guest rooms, kitchens, and communal areas.

- Food Processing: Cleaning and sanitizing equipment without the risk of chemical contamination.

6. Public Perception and Compliance

The integration of environmentally friendly cleaning technologies like electrolyzed water can enhance a facility’s reputation and help achieve compliance with evolving regulations and certifications.

The integration of environmentally friendly cleaning technologies like electrolyzed water can enhance a facility’s reputation and help achieve compliance with evolving regulations and certifications.

- Consumer Trust: Facilities that prioritize sustainable and safe cleaning practices are likely to gain trust and loyalty from customers, clients, and guests.

- Regulatory Alignment: Many industries are adopting stricter cleaning and environmental standards, and electrolyzed water systems can help facilities stay ahead of compliance requirements.

- Green Certifications: Facilities using electrolyzed water may qualify for certifications such as LEED (Leadership in Energy and Environmental Design) or WELL Building Standard, improving their market positioning.

7. Scalability and Long-Term Benefits

As facilities grow or change, electrolyzed water systems can scale accordingly, making them a future-proof investment.

- Customizable Output: Systems can be adjusted to produce solutions in volumes that match operational demands.

- Consistent Performance: Unlike chemical products that degrade over time, on-demand production ensures fresh and potent cleaning solutions.

- Cost Predictability: Once installed, operational costs are low and predictable, offering long-term financial stability.

Integrating electrolyzed water into facility cleaning practices is more than a cleaning innovation—it’s a paradigm shift toward safer, greener, and more efficient operations. With its proven safety, effectiveness, and adaptability, electrolyzed water offers a transformative solution that meets the demands of modern facilities while prioritizing the well-being of workers, the environment, and the communities they serve.

Implementing Electrolyzed Water Systems

To effectively integrate electrolyzed water into cleaning practices, facilities can consider the following steps:

- Assess Cleaning Needs: Evaluate the specific cleaning and disinfection requirements of the facility to determine which products can be replaced with electrolyzed water solutions.

- Install On-Site Generation Systems: Invest in electrolyzed water generation equipment that suits the facility’s size and operational demands. These systems can produce the necessary solutions on demand, ensuring freshness and efficacy.

- Train Staff: Provide comprehensive training for cleaning personnel on the proper use and handling of electrolyzed water, emphasizing safety protocols and application techniques.

- Monitor and Maintain: Regularly monitor the performance of the electrolyzed water system and maintain the equipment to ensure consistent production of effective cleaning and disinfecting solutions.

Electrolyzed water presents a compelling solution for modern cleaning challenges, offering effective disinfection while enhancing worker safety and promoting environmental sustainability. By understanding its science and benefits, and thoughtfully integrating it into facility cleaning practices, organizations can achieve cleaner, safer, and more sustainable environments.