The products we use to clean and disinfect our homes and businesses have their roots in the early 1900s. Due to both world wars, shortages developed with the naturally derived products used to manufacture traditional soaps. In response, scientists invented the synthetically produced chemical concoctions we now know as detergents.

Everything taken for granted today about the sanitization industry – good and bad – flowed from this innovation. That includes modern products’ effectiveness and their wide range of applications, but also their long, obscure lists of toxic ingredients, which can cause profound damage to human health and the environment.

What’s even less well known is that around the same time modern detergents emerged, another technological seed was planted in the form of “electrolyzed water.” Over a hundred years later, this seed is now bearing fruit. Today, electrolyzed water has all the qualities necessary to remake cleaning as profoundly as conventional detergents did before it.

What is electrolyzed water?

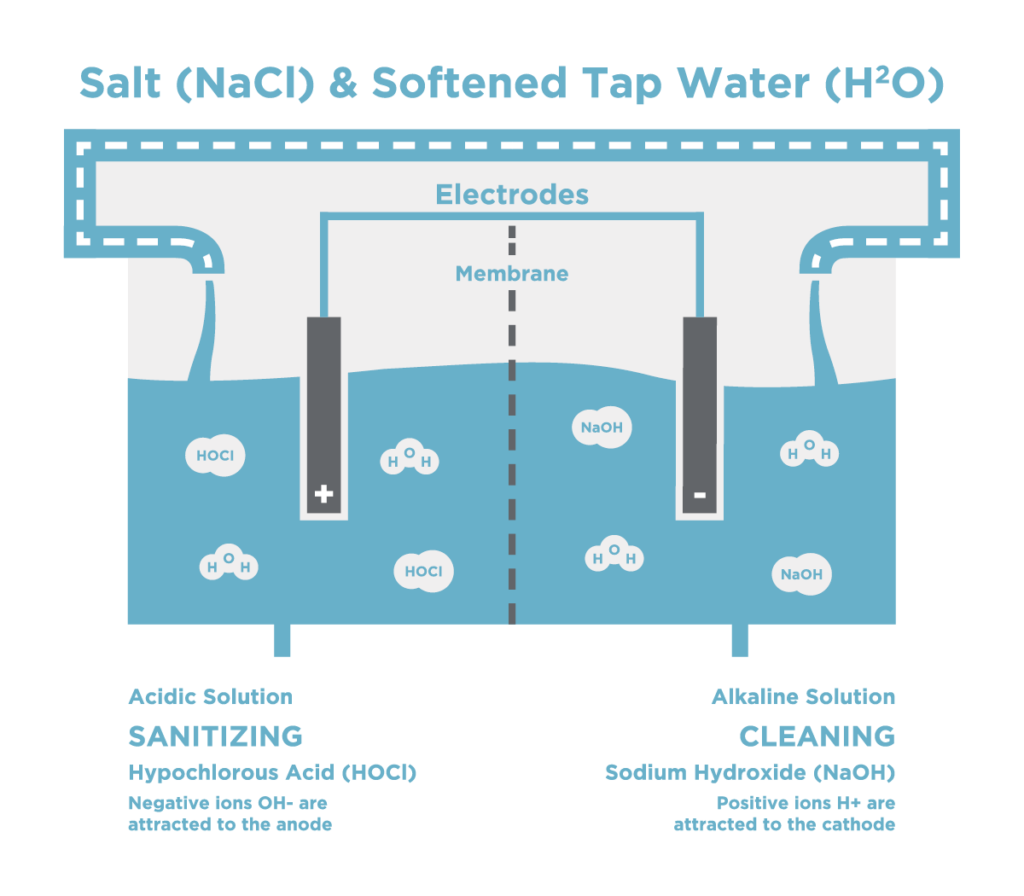

Deriving from a chemical reaction, electrolyzed water is produced through a process called electrolysis. When electricity activates the ions in a saltwater solution, it creates two entirely new solutions that bring all the upside of conventional products while eliminating most of the downsides.

This chemical reaction hinges on the respective positive and negative charges of the sodium and chloride molecules that compose the salt, which separate from each other when the electric current is applied. Then, they bond with the water’s hydrogen and oxygen molecules, creating a hypochlorous acid disinfectant (HOCl) and a sodium hydroxide alkaline cleaner and degreaser (NaOH).

How it works

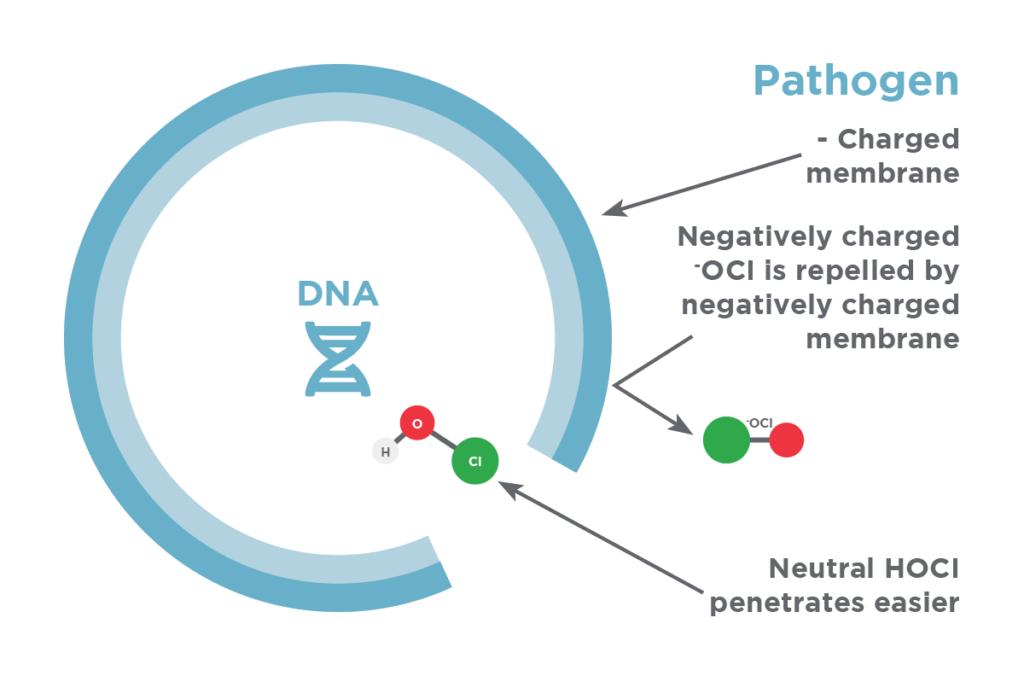

The high level of oxidation in the HOCl disinfectant, which is 80-120 times more effective than bleach, damages the cell walls of pathogens, causing them to fill up with water until they burst. Crucially, this process can take place within less than ten seconds of contact time, which makes it extremely powerful as well as being simple and easy to use.

The NaOH cleaner, meanwhile, is a heavy-duty degreaser that breaks down fat, oil, and proteins. It’s effective against grease and mold, eliminates odor, and can be used on both hard or soft surfaces – including carpeting and upholstery. Like hypochlorous acid, it is approved by both the USDA and the FDA.

Most distinctively, both solutions do not contain VOCs, phenols or harsh chemicals, as they are produced with just two ingredients: water and salt. In fact, HOCl is the same substance our bodies produce to fight infection, which is why it’s also used for eye, wound, and veterinary care.

The status quo is harming our health

The same is far from being true of the chemicals in typical cleaning products. Many of them are packed full of volatile organic compounds (VOCs), which have been connected to a wide range of health problems, including cancer, liver and kidney damage, central nervous system damage, and more. Other common ingredients, like ammonia and bleach, are also highly toxic.

Much of what is marketed as “natural” alternatives isn’t much better. Fragrances are often to blame. Because fragrances qualify as “trade secrets” under U.S. law, companies don’t have to disclose them on product labels. Harmful VOCs, as well as phthalates (chemicals that have been connected with infertility, birth defects, and heart disease) are frequently smuggled into cleaning products through this loophole.

One study analyzed 17 so-called natural products and found that every last one “gave off at least one potentially toxic chemical.” The study also found that 90% of toxic chemical ingredients weren’t listed on the labels, green or otherwise.

Electrolyzed water’s delayed triumph

Given electrolyzed water’s clear advantages, a question naturally arises: why has it taken so long to catch up? Before answering this question, it’s worth noting that electrolyzed water has already gained wide adoption in countries like Japan, where electrolyzed water has been used for decades in cleaning and disinfecting applications.

But there are a few factors that have historically limited the spread of electrolyzed water on a larger scale: first, electrolyzed water is unstable, which means it loses potency in just a few weeks. This comparatively short shelf life makes it difficult for many businesses to keep enough inventory on hand.

The second crucial drawback of standard electrolyzed water generators is that significant amounts of salt would be left in the final solutions, which can be corrosive to metals and sensitive equipment. For any business that can’t afford to see its physical assets rapidly deteriorate (i.e. most of them), this was a fatal flaw.

But Viking Pure has solved both of these problems. As for the first, Viking Pure provides an onsite generator that allows businesses to produce both the cleaner and disinfectant solutions as needed in-house. Facilities that lease these generators can produce as much solution as they need on-demand, at a fixed monthly cost. For customers who purchase bottles of the solutions from a distributor, each bottle is marked with an expiration date to enable staff to verify the potency of the solutions.

To solve the second problem – salt residue and corrosion – Viking Pure’s generators use a patented technology where the salt does not enter the electrolytic cell and therefore is not added to the output solutions. This innovation means our version of electrolyzed water can be used on virtually any surface without any fear of corrosion, dramatically increasing its potential applications.

Now, with the most important obstacles out of the way over a century after its invention, the triumph of electrolyzed water seems not a matter of if – but when.